Best Oil and Gas Maintenance in Nigeria

Oil and Gas Maintenance in Nigeria | The oil and gas industry in Nigeria has long been one of the country’s key drivers of economic growth and industrial development. However, as the industry matures and faces growing challenges, maintaining and optimizing its infrastructure has become critical to its continued success. In recent years, advancements in technology have played an increasingly significant role in transforming the way oil and gas assets are maintained, leading to improved efficiency, safety, and cost-effectiveness. This article will explore the best oil and gas maintenance technologies currently revolutionizing the sector in Nigeria.

The Role of Maintenance in the Oil and Gas Sector

Before diving into the technologies themselves, it’s important to understand the role of maintenance in the oil and gas industry. In this capital-intensive sector, infrastructure includes everything from oil rigs, pipelines, storage tanks, and refineries to offshore platforms and pumping stations. Maintaining this infrastructure involves a variety of tasks designed to ensure the assets are operating at peak efficiency while avoiding costly downtime and extending their operational life.

Maintenance can be divided into several categories:

- Preventive Maintenance: This involves regularly scheduled tasks aimed at preventing breakdowns before they happen. It’s the foundation of most maintenance strategies.

- Predictive Maintenance: This type of maintenance uses data analytics and sensors to predict when an asset will fail, allowing operators to address the issue before it occurs.

- Corrective Maintenance: This type of maintenance happens after a failure occurs. It’s reactive and focuses on fixing the issue at hand.

For Nigeria, where the oil and gas sector represents a significant portion of national revenue, adopting cutting-edge maintenance technologies is crucial to ensure that its oil fields and associated infrastructure remain operational and productive.

The Best Oil and Gas Maintenance Technologies in Nigeria

1. Predictive Maintenance and IoT Sensors

One of the most impactful advancements in oil and gas infrastructure maintenance in Nigeria has been the integration of predictive maintenance technologies, often powered by the Internet of Things (IoT). IoT-enabled sensors are embedded into critical assets like pumps, compressors, and pipelines to collect real-time data on equipment performance.

By continuously monitoring variables such as temperature, vibration, pressure, and flow rate, these sensors send data to central control systems that use artificial intelligence (AI) and machine learning (ML) algorithms to predict potential failures before they occur. This helps maintenance teams in Nigeria to schedule repairs and replacements proactively, minimizing downtime and extending the life of expensive infrastructure.

One of the key benefits of predictive maintenance is that it allows for condition-based maintenance, meaning assets are only serviced when data indicates that maintenance is actually required, as opposed to following a fixed schedule. This reduces unnecessary maintenance costs and improves overall efficiency.

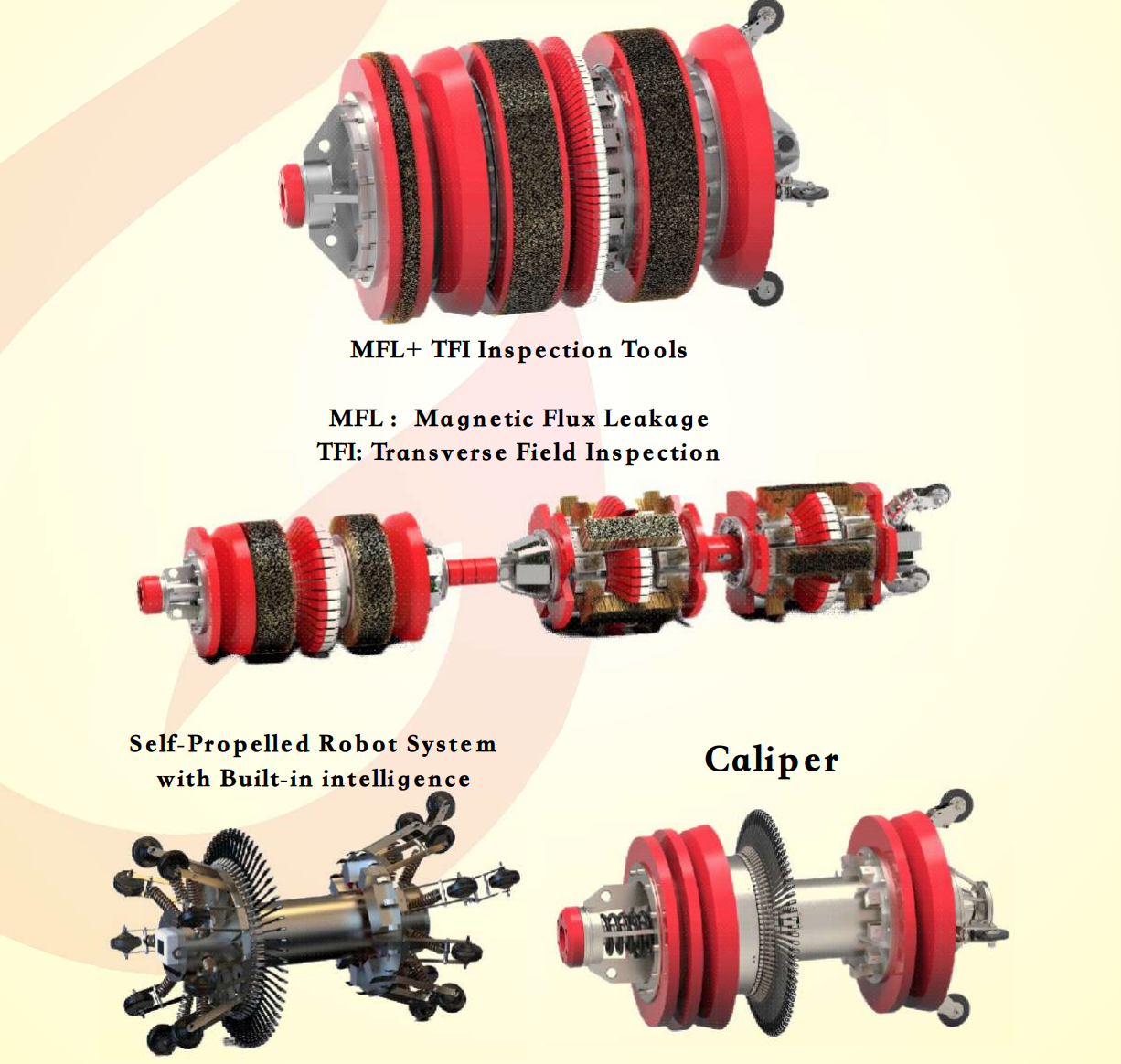

2. Drones and Robotics for Remote Inspections

With the rugged terrain and remote locations of many oil and gas facilities in Nigeria, conducting inspections and routine maintenance has historically been a challenging and dangerous task. The use of drones and robotics is helping to address these challenges by providing remote inspection capabilities.

Drones equipped with high-resolution cameras, infrared sensors, and other advanced technologies can fly over offshore rigs, pipelines, or refineries to inspect equipment and monitor conditions. They can easily access hard-to-reach areas such as tall structures, submerged pipelines, and isolated oil platforms, reducing the need for human intervention in hazardous environments.

Robotic technology is also evolving rapidly in the oil and gas industry. Autonomous underwater vehicles (AUVs) and robotic arms can carry out maintenance tasks underwater, such as inspecting pipelines, cleaning tanks, or repairing subsea valves. This not only enhances safety but also improves the speed and accuracy of inspections.

3. Artificial Intelligence and Machine Learning | Best Oil and Gas Maintenance in Nigeria

Artificial Intelligence (AI) and Machine Learning (ML) are transforming maintenance practices across the global oil and gas industry, and Nigeria is no exception. AI algorithms can process vast amounts of data generated by sensors, drones, and other equipment to identify patterns, predict failures, and optimize asset performance.

By analyzing historical data alongside real-time inputs, AI can anticipate operational issues and suggest specific interventions, which helps oil and gas operators in Nigeria reduce the frequency of expensive repairs. Moreover, AI tools can automatically recommend maintenance schedules, select the right parts for repairs, and even guide technicians through complex procedures, further minimizing human error and downtime.

Machine Learning algorithms are used to improve predictive maintenance systems by continuously learning from the data gathered and refining predictions over time. For instance, the system can become more accurate in forecasting the remaining useful life of a pump or compressor based on trends in operational data, weather conditions, and environmental factors.

4. Digital Twin Technology | Best Oil and Gas Maintenance in Nigeria

Digital twin technology involves creating a virtual replica of physical assets, which is becoming a game-changer for oil and gas maintenance in Nigeria. A digital twin is a real-time digital model that mimics the operations, conditions, and behavior of a physical asset such as a refinery, pump, or offshore platform.

By using data collected from sensors and IoT devices, digital twins provide operators with a comprehensive view of how their assets are performing at any given moment. Maintenance teams can simulate various scenarios, test potential changes, and optimize performance in a risk-free virtual environment before applying any modifications to the actual asset.

For oil and gas companies in Nigeria, the ability to visualize the performance of their equipment remotely and make data-driven decisions can dramatically reduce maintenance costs, improve operational uptime, and increase overall safety. Digital twins also allow for more precise planning and scheduling of maintenance activities, minimizing disruptions to production.

5. Cloud Computing and Big Data Analytics | Best Oil and Gas Maintenance in Nigeria

Cloud computing and big data analytics are two more technological advancements making a significant impact on oil and gas infrastructure maintenance in Nigeria. Cloud platforms allow for seamless data storage and real-time analysis of the vast amounts of data generated by sensors, drones, IoT devices, and operational systems.

With cloud-based systems, oil and gas operators can remotely access real-time maintenance data, monitor asset performance, and collaborate across locations. Big data analytics processes this data to uncover insights and trends that would be difficult or impossible to detect using traditional methods. By applying predictive models to large data sets, maintenance teams can optimize scheduling, minimize downtime, and make more informed decisions about the future of their assets.

In Nigeria, where many oil and gas assets are located in remote areas, cloud computing provides an efficient way for maintenance teams to access and analyze data from anywhere, ensuring that maintenance decisions are based on the most up-to-date information.

6. Augmented Reality (AR) and Virtual Reality (VR) | Best Oil and Gas Maintenance in Nigeria

Augmented reality (AR) and virtual reality (VR) technologies are being employed to train technicians, simulate maintenance procedures, and assist in troubleshooting. For oil and gas operators in Nigeria, these technologies provide a cost-effective way to enhance the skills of maintenance personnel and reduce the risk of human error during critical tasks.

With AR glasses or VR headsets, maintenance technicians can access detailed instructions and schematics while performing repairs or inspections, providing them with real-time guidance without needing to consult paper manuals or online resources. This technology can also be used for remote support, allowing experienced technicians to virtually “see” through the eyes of field workers and provide real-time troubleshooting assistance.

Conclusion: The Future of Oil and Gas Maintenance in Nigeria

The oil and gas industry in Nigeria is undergoing a major transformation, and technology is at the forefront of this change. Predictive maintenance, drones, AI, digital twins, and other cutting-edge tools are helping to improve the efficiency, safety, and cost-effectiveness of oil and gas infrastructure maintenance. By embracing these technologies, Nigerian operators can ensure that their assets continue to perform at peak levels while reducing the risk of costly downtime and catastrophic failures.

As the oil and gas industry continues to evolve, it’s clear that the future of maintenance in Nigeria will be driven by digital innovation. By leveraging the best maintenance technologies available today, Nigeria can position itself as a global leader in efficient and sustainable oil and gas operations.

Read about our Engineering Procurement and Construction in Nigeria Learn about NMDPRA