Best Offshore Facility Maintenance in Nigeria: Overcoming Industry Challenges

Offshore Facility Maintenance in Nigeria, Offshore platforms such as FPSOs (Floating Production Storage and Offloading units), drilling rigs, and subsea systems are critical components in this ecosystem. However, maintaining these offshore facilities comes with its own unique set of challenges. From harsh environmental conditions to logistical complications, the offshore maintenance landscape in Nigeria is a complex one. This article explores the challenges associated with offshore facility maintenance in Nigeria and presents viable solutions for overcoming them.

Harsh Environmental Conditions and Offshore Facility Maintenance in Nigeria

One of the foremost challenges in offshore facility maintenance in Nigeria is dealing with extreme environmental conditions. The Gulf of Guinea, where many of Nigeria’s offshore oil installations are located, experiences unpredictable weather, high humidity, corrosive salty air, and intense wave activity. These conditions accelerate wear and tear on offshore infrastructure.

Corrosion and Structural Integrity:

Steel structures, pipelines, and machinery are constantly exposed to saltwater, leading to aggressive corrosion. The integrity of critical components like risers, pipelines, and load-bearing structures can be compromised without regular and proactive maintenance.

Solution:

Advanced corrosion-resistant materials and coatings, such as duplex stainless steels and polymer-based coatings, are being increasingly adopted. Additionally, regular cathodic protection systems and remote monitoring for corrosion levels help mitigate risks.

Logistical Constraints in Offshore Facility Maintenance in Nigeria

Maintaining offshore facilities in Nigeria involves complex logistics. Moving personnel, equipment, and materials to and from offshore platforms requires coordination of helicopters, supply vessels, and crew boats. Bad weather often delays transport, while high operational costs burden maintenance budgets.

Limited Access to Skilled Labor and Spare Parts:

Delays are further compounded by the shortage of skilled offshore technicians and the unavailability of critical spare parts locally, which can significantly affect the Mean Time to Repair (MTTR).

Solution:

Developing local supply chains and investing in indigenous manpower training programs can reduce dependency on foreign technicians and improve turnaround times. Government and private partnerships like the Nigerian Content Development and Monitoring Board (NCDMB) are vital in this regard.

Security Concerns in Offshore Facility Maintenance in Nigeria

Security is a significant concern for offshore operators in Nigeria, especially in the Niger Delta region. Piracy, militant activities, and vandalism pose serious risks to personnel and infrastructure.

Impact on Maintenance Operations:

Maintenance schedules are often delayed or canceled due to security threats. Contractors may refuse to work in certain zones, and insurance costs are elevated, increasing the total cost of ownership for offshore assets.

Solution:

Enhanced maritime security cooperation between government agencies and private operators has led to the deployment of naval escorts and surveillance systems around critical infrastructure. The integration of technology such as drones, radar systems, and AI-based threat detection further boosts security operations.

Regulatory and Compliance Challenges in Offshore Facility Maintenance in Nigeria

Navigating Nigeria’s regulatory landscape can be challenging for both local and international oil companies (IOCs). Offshore maintenance operations must comply with a myriad of standards, including those set by the Department of Petroleum Resources (DPR), Nigerian Upstream Petroleum Regulatory Commission (NUPRC), and international bodies like the API and ISO.

Permit Delays and Bureaucracy:

Securing permits for offshore maintenance can be time-consuming, leading to unnecessary downtime. Regulatory ambiguity and changes in policy can also cause confusion and non-compliance.

Solution:

Proactive engagement with regulatory bodies and transparent documentation can ease the permit acquisition process. Companies that embed compliance into their operational strategy and maintain updated audit trails tend to face fewer disruptions.

Cost Management in Offshore Facility Maintenance in Nigeria

Offshore maintenance is inherently expensive. For operators in Nigeria, this challenge is magnified by high inflation, currency fluctuations, and limited access to foreign exchange. These economic pressures make it difficult to budget accurately for long-term maintenance programs.

Balancing Cost and Efficiency:

Operators are often tempted to cut corners to save costs, which can compromise safety and operational integrity in the long run.

Solution:

Adopting predictive maintenance powered by IoT and data analytics allows operators to identify potential failures before they occur, thereby optimizing maintenance intervals and reducing unplanned downtime. Life-cycle cost analysis and strategic vendor partnerships can also help control costs more effectively.

Technological Limitations in Offshore Facility Maintenance in Nigeria

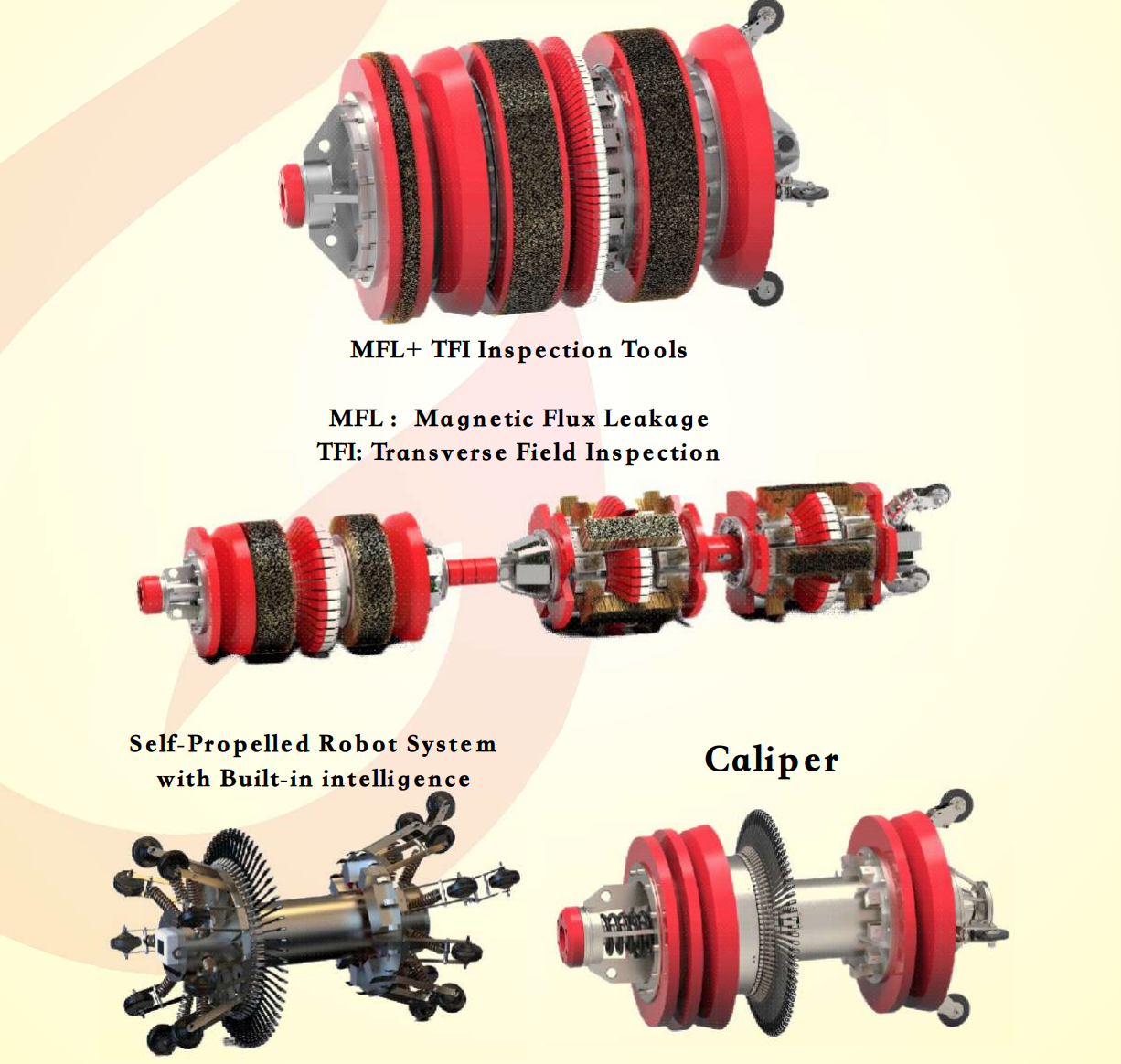

Nigeria’s offshore oil industry has been relatively slow in adopting cutting-edge technologies that enhance maintenance efficiency. Traditional inspection methods like manual checks and divers are still commonly used.

Limited Use of Automation and Digital Tools:

The global offshore maintenance industry is rapidly evolving with the adoption of autonomous underwater vehicles (AUVs), drones, digital twins, and remote inspection technologies. However, these technologies are still underutilized in Nigeria.

Solution:

A shift towards digitalization is essential. The use of asset integrity management software, real-time condition monitoring systems, and digital twins can provide a comprehensive view of asset health and optimize decision-making. Strategic investments and partnerships with tech firms can accelerate this transformation.

Human Capital Development for Offshore Facility Maintenance in Nigeria

A critical enabler for offshore maintenance success is the availability of trained personnel. While Nigeria has a growing pool of engineers and technicians, specialized offshore maintenance skills are still scarce.

Brain Drain and Training Gaps:

Many skilled professionals migrate abroad in search of better opportunities, creating a vacuum in local expertise. Meanwhile, training facilities and institutions may not be equipped with the latest offshore technologies.

Solution:

Collaboration between oil companies, academic institutions, and government agencies can bridge the training gap. Scholarship programs, technical internships, and offshore simulation training centers can play a vital role in developing the next generation of offshore maintenance experts.

Sustainability and Environmental Considerations in Offshore Facility Maintenance in Nigeria

Sustainable offshore maintenance is becoming increasingly important in the global energy sector. Environmental accidents like oil spills not only cause ecological damage but also lead to reputational and financial losses.

Environmental Risk During Maintenance:

Tasks like subsea welding, chemical cleaning, or pipeline flushing carry the risk of accidental discharges if not properly managed.

Solution:

Implementing Environmental Management Systems (EMS), complying with international best practices such as ISO 14001, and using eco-friendly maintenance materials are essential steps. Regular environmental impact assessments and response plans ensure minimal disruption to marine life and local communities.

Conclusion: The Way Forward for Offshore Facility Maintenance in Nigeria

Maintaining offshore facilities in Nigeria is a multifaceted challenge requiring coordinated efforts across technology, policy, security, and workforce development. Despite the hurdles, the Nigerian oil and gas industry has shown resilience and adaptability. By embracing digital technologies, strengthening local capacity, improving logistics, and enhancing security protocols, Nigeria can significantly improve its offshore maintenance landscape.

The government’s commitment to local content development and infrastructure investment, combined with private sector innovation, provides a strong foundation for the future. As the global energy transition unfolds, ensuring the operational integrity and environmental sustainability of offshore facilities will remain a top priority.

Learn About us and alos our Engineering Procurement and Construction in Nigeria and Nigerian Upstream Petroleum Regulatory Commission (NUPRC)