Intelligent Pigging in Nigeria: Pioneering Pipeline Safety and Innovation with Torch Energy Group

Intelligent Pigging in Nigeria, Nigeria’s energy sector is defined by a vast web of pipelines transporting crude oil, natural gas, and refined petroleum across remote and urban regions. As vital as these conduits are, their maintenance presents significant challenges—corrosion, wear, and potential failure all threaten national production and environmental safety. That’s where Intelligent Pigging comes into play: a non-destructive, tech-driven inspection method reshaping pipeline maintenance in Nigeria.

Among the few players leading this transformation, Torch Energy Group stands at the forefront—delivering innovative, reliable, and scalable intelligent pigging solutions for the most demanding pipeline networks.

What is Intelligent Pigging?

Intelligent pigging—also known as smart pigging—involves the use of inspection devices called “pigs” that move through pipelines to collect critical data. These devices are equipped with sensors and diagnostic tools to detect internal issues like corrosion, metal loss, deformation, and cracks, all without interrupting pipeline operations.

Unlike traditional pigging (used primarily for cleaning), intelligent pigs perform real-time data collection and integrity assessments. It’s like getting an MRI scan of your entire pipeline—while it’s still in use.

How Intelligent Pigging Works

The intelligent pigging process is systematic and involves several stages:

1. Pre-Inspection Planning

Before deployment, engineers define the pipeline route, determine the inspection scope, and assess operational conditions such as product flow and pressure. This helps select the right pig type and technology.

2. Launching the Pig

The pig is inserted into the pipeline through a device called a pig launcher. It’s then propelled through the pipeline by the flow of the product (oil, gas, or water).

3. Data Collection During Transit

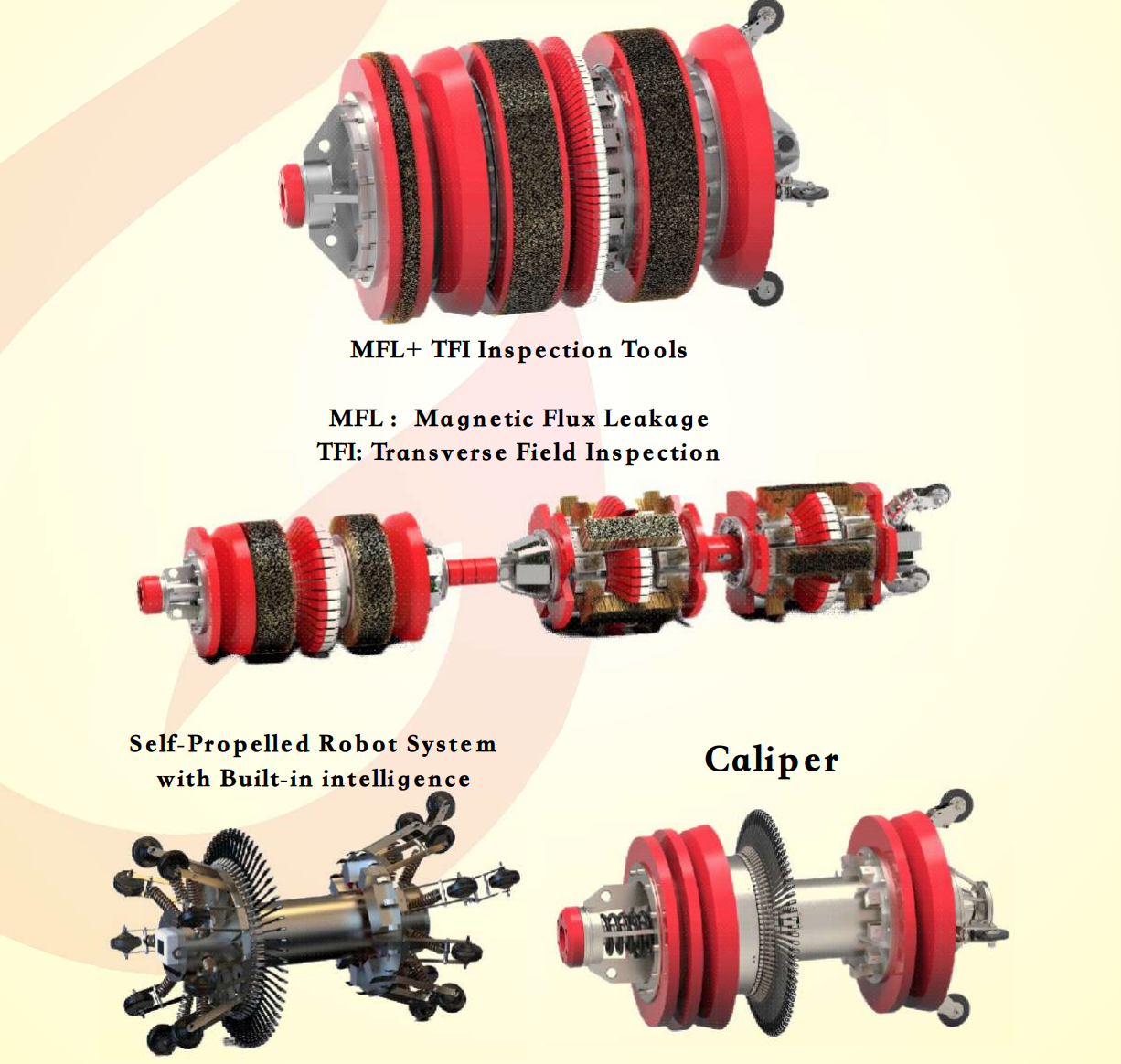

As the pig travels, it records valuable data using advanced technologies like:

- Magnetic Flux Leakage (MFL): Detects corrosion and pitting.

- Ultrasonic Testing (UT): Measures wall thickness and internal flaws.

- Caliper Sensors: Detect dents, bends, or ovalities in the pipeline.

4. Receiving and Analyzing Data

At the end of its run, the pig is retrieved using a receiver. Engineers then extract and analyze the data to identify and prioritize pipeline threats.

5. Maintenance and Decision Making

Based on the findings, maintenance schedules are created, allowing proactive intervention and extending the lifespan of the pipeline infrastructure.

The Importance of Intelligent Pigging in Nigeria

1. Addressing Infrastructure Age

Many pipelines in Nigeria are decades old and at risk of failure. Intelligent pigging identifies degradation before it leads to spills or explosions, saving lives, money, and the environment.

2. Regulatory Compliance

Agencies like the Department of Petroleum Resources (DPR) and Nigerian Upstream Petroleum Regulatory Commission (NUPRC) mandate periodic integrity inspections. Intelligent pigging supports full regulatory adherence.

3. Minimizing Downtime

By detecting issues early, operators can perform scheduled maintenance rather than emergency shutdowns—significantly reducing downtime and financial losses.

4. Environmental Protection

Pipeline leaks not only hurt business but also wreak havoc on ecosystems and communities. Intelligent pigging prevents spills and supports sustainable operations.

Torch Energy Group: Nigeria’s Leader in Intelligent Pigging

When it comes to pipeline inspection and integrity assurance, Torch Energy Group is Nigeria’s leading authority. With cutting-edge tools and a highly skilled engineering team, the company delivers intelligent pigging services across the country’s most critical pipeline networks—both offshore and onshore.

Why Torch Energy Group Stands Out in Intelligent Pigging in Nigeria

- Advanced Tools: From high-resolution MFL pigs to ultrasonic and geometry tools, Torch Energy uses industry-leading technology tailored to Nigeria’s unique terrain and pipeline challenges.

- Local Expertise: Unlike international firms, Torch Energy understands the environmental, logistical, and regulatory nuances of operating in Nigeria.

- Comprehensive Services: Beyond pigging, they provide full-spectrum pipeline integrity management, including cleaning, gauging, inspection, data interpretation, and risk assessment.

- Safety First: Their commitment to safety and environmental responsibility puts them ahead of competitors.

- Trusted by Industry Giants: Torch Energy Group is a go-to contractor for major oil and gas operators, with an impressive track record of successful deployments.

Visit Torch Energy Group for more on their intelligent pigging capabilities.

Technological Advances in Nigeria’s Pigging Sector

There’s a shift towards digitization and automation in Nigeria’s pipeline inspection industry. Companies like Torch are integrating real-time cloud analytics and AI-assisted diagnostics to provide deeper insights, faster.

Meanwhile, research institutions are also collaborating with local firms to develop low-cost intelligent pigs using 3D printing and modular sensor designs—making the technology more accessible across Africa.

Challenges and Opportunities Intelligent Pigging in Nigeria

Challenges:

- High Capital Costs: Advanced pigs and sensors are expensive, and not all operators can afford regular inspections.

- Skill Shortage: Nigeria still faces a shortage of skilled pigging technicians and data analysts.

- Infrastructure Gaps: Some pipelines lack launcher and receiver stations, limiting intelligent pigging access.

Opportunities:

- Training & Capacity Building: Ongoing investments in training by companies like Torch are grooming a new generation of local pipeline engineers.

- Innovation Grants: Government incentives can stimulate research in low-cost inspection technologies.

- Export Potential: With its expertise, Nigeria could soon offer pigging services to neighboring countries.

FAQs About Intelligent Pigging in Nigeria

Q1: Is intelligent pigging mandatory for pipeline operators in Nigeria?

Yes. Regulatory bodies often require periodic integrity assessments using intelligent pigging or other approved NDT methods.

Q2: How often should pigging be done?

It depends on the pipeline’s age, product type, and environmental risks. In general, operators schedule intelligent pigging every 3–5 years.

Q3: Can intelligent pigs inspect offshore pipelines?

Absolutely. Companies like Torch Energy Group provide intelligent pigging solutions for both offshore and onshore installations.

Q4: What is the difference between intelligent pigging and traditional pigging?

Traditional pigging cleans pipelines; intelligent pigging inspects them for damage and defects using sensors and analytics.

Q5: How long does the pigging process take?

Inspection can take a few hours to a couple of days, depending on the pipeline length and pig type. Analysis and reporting may take another few days.

Final Thoughts Intelligent Pigging in Nigeria

Nigeria’s energy future depends on safe, efficient, and reliable infrastructure. Intelligent pigging has emerged as the gold standard in pipeline integrity, helping operators prevent leaks, reduce downtime, and comply with stringent regulations. With Torch Energy Group leading the charge, Nigeria is not just keeping up with global standards—but setting them.